Do you ever wonder what is happening under the hood of your car? Despite the fact that it may look like a maze of steel and wire, it isn’t that complicated.

In the blog, We’ll outline the fundamentals of how a car engine works, describe the functions of important parts, point out some of the frequently occurring problems that you may experience and provide guidance on engine performance improvement.

How Does a Car Engine Work?

The traditional internal (i.e., automotive) gasoline engine of the classical automotive internal (i.e., automotive) four-stroke Otto engine cycle machine is a four-stroke Otto cycle mechanism. This cycle comprises four stages:

Intake: As the piston moves downward, the engine draws air at the intake valve. On the one hand, the fuel is mixed in the air flux, generating a flammable mixture.

Compression: When the piston moves up, the air-fuel ratio is squeezed into a new smaller volume. As a result of compression, temperature and pressure rise, and the entire system is restarted at the point of ignition) (i.e.

Power: A spark plug ignites the compressed mixture. The produced blast “shocks” the piston violently, which causes the rotational movement of the crankshaft, and therefore kinetic energy of the crankshaft is transferred to the car wheels, accordingly.

Exhaust: In each cycle, the piston rises to the top of the cylinder and then actuates the eviction of the burnt gases out of the exhaust valve.

Engine Parts and Functions

- Engine block

Components such as cylinders and the engine core are positioned within the engine block. The cast iron or aluminium alloy solid body of the engine, i.e., the fixed outer casing of the engine, is an indeformable and rigid outer shell of the engine which instils the required internal structure to withstand internal stresses generated by combustion.

- Cylinder

It’s in the cylinders that the combustion reaction takes place. Cylindrical chambers are precision machined into the engine block. Quantization of the number might exist in them, and so both might contribute to the strength of the machine and the cumulative displacement. Systems with 3, 4, 6 and 8 cylinders are each used in the car.

- Cylinder head

The cylinder head is bolted down on the engine block, it includes the cylinder, and the valvetrain as well as the spark plugs and the camshaft.

- Valves

Valves control the air and fuel supply to the cylinder and the exhaust of the cylinder combustion gases. Intake valves can deliver the air-fuel mixture into the cylinder, and exhaust valves can deliver the burnt gases out of the cylinder respectively. Number of valves of a cylinder is [between 2 and 5].

- Camshaft

The camshaft closes and opens the engine valves. It is asynchronous with the crankshaft using a timing belt or chain. The camshaft likewise permits, during the period of the engine cycle of combustion that is a portion of the intake cycle, to opening and close correctly the intake and exhaust valve(s).

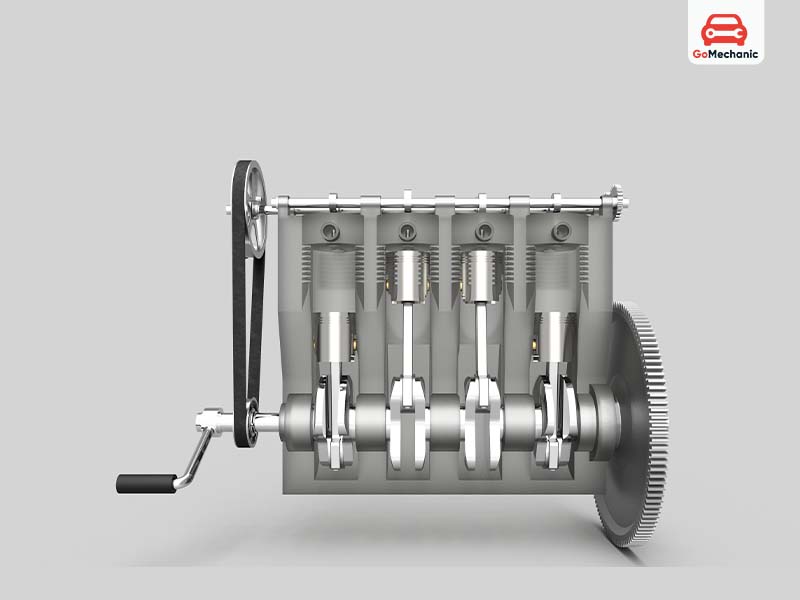

- Pistons

Cages containing cylindrical apparatus (e.g., cylinders) along which the subject is able to slide up and down. Thereby, the piston rings “seal” them, and the maximum pressure is inside between the cylinder wall.

- Connecting rods

Connecting rods are the means by which the pistons relate to the crankshaft. Their main role is the linear movement of the pistons in order to rotate the crankshaft.

- Crankshaft

The crankshaft is a long, rotating cylinder at the bottom of the engine block and cylinders. Stroke of the pistons are linearized and as such are modeled as rotation around which the gearbox can spin with respect to the vehicle wheel.

- Timing belt/chain

In the indexing, the timing belt or timing chain drives the rotational synchronisation between the crankshaft and the camshaft. On the other hand, this synchronization is rather mandatory in order to make sure that the valves are opened and closed at the correct moment and in the correct way regarding the piston position.

- Spark plugs

Spark plugs ignite the air-fuel mixture within the cylinders. It generates a spark which is in turn utilized to arc at a convenient time during which the device is compressed i.e., during the compression stroke. A single spark plug per cylinder is typical for most engines but the use of a couple of them is sometimes implemented (and maybe still) by a few manufacturers.

- Fuel injectors

A fuel injector is an extremely tiny spray nozzle, which can be electrically closed, thus its delivery can be strictly controlled in the air/fuel rate for the chamber.

- Exhaust system

The exhaust system expels burnt gases from the engine. It is a set part, which for example comprises exhaust manifold, catalytic converter, and muffler. This device is not only in shape to detoxify the wastewater but also the toxic gases and noise.

- Lubrication system

The lubricator system has enough lubrication oil, so there is a reduction in friction and wear. It encompasses the oil sump/pan, the oil pump, the oil filter, and all the oil lines for the engine oil.

- Cooling system

The cooling system prevents the engine from overheating. It flows cooling fluid through the engine block and cylinder head where it cools the heat, and then it sends the heat to the radiator. Elements, e.g., water pump, thermostat and radiator are part of the system.

- Engine management systems

Engine control is, today, indeed provided by rather sophisticated engine control units (ECUs) that control parameters for high performance, high efficiency and emissions and assistance from Electronic Control Units (ECUs). These ecuS are provided with information from several sensors measuring engine parameters.

Different Types of Car Engines

- Inline Engines

Inline engines (also referred to as straight engines) is a type of engine layout, characterized by a group of cylinders arranged in a parallel line. They are extremely popular in fitting small vehicles and are known to give fuel consumption cost benefits because of their small surface area and hence low friction. Inline engines with 3, 4, 5 and 6 cylinders offer a range.

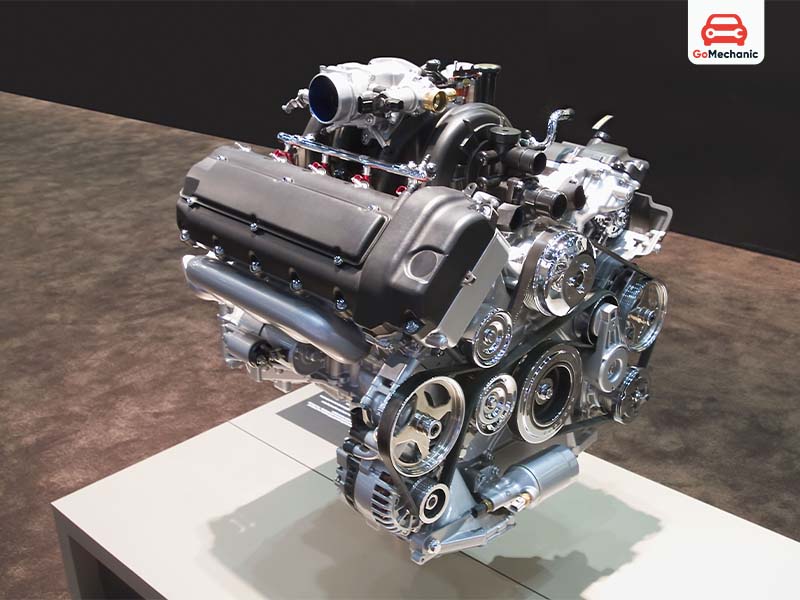

- V-Shaped Engines

V-engines are constructed by cylinder(s) in two row(s) with steep angles (e.g., 60 or 90 relative to an axis). They come in V6, V8, V10, and V12 configurations. Engines with a tradeoff between performance and space economy are widely used for high-performance computing and luxury automobiles.

- Boxer Engines

Boxer engines (i.e., flat engines) are defined by the parallel, horizontal, arrangement of the cylinders with respect to the crankshaft. However, this design has the benefit of the reduced centre of gravity (i.e., stability, control, handleability, and ease of manipulation). Subaru is noted for the implementation of the boxer engines in its vehicles.

- Rotary Engines

Internal combustion rotary engines (also called Wankel engines) have a valvetrain which involves using triangular rotors being turned inside housings rather than some approximation of a piston-type sliding path. Rotary engine cars are the epitome of the Mazda RX-7 and RX-8. They are known for their smooth, high-revving characteristics.

- Diesel Engines

For diesel engines, one four-stroke cycle (ie, as in a gasoline engine’s 4-stroke cycle) is employed, with diesel oil acting as fuel instead of fuel. They are famous for fuel economy and high torque bandwidth and are suitable for heavy duty tasks like trucks and buses.

- Hybrid Engines

Hybrid machines are a combination of one internal combustion engine and an electric rotor driven by an energy source, which is a battery. Since motors are capable of producing DC feed power at low speeds, they can be operated with higher efficiencies and low emissions.

- Electric Engines

Electric motors (or electric engines) are powered exclusively by the power delivered by the battery. Electric vehicles (EVs) have become extremely popular because of their near-zero emissions and the property of high peak torque.

- Hydrogen Fuel Cell Engines

The engines of hydrogen fuel cell cars are fed with hydrogen gas in order to convert the energy in hydrogen gas into electricity in order to turn an electric motor. These engines generate water vapour only and are being researched as a viable energy solution.

- Turbocharged and Supercharged Engines

Forced induction is applied to a turbocharged or supercharged engine to obtain power. Turbochargers and superchargers compress air into the engine. Such that they enable the combustion to consume more fuel to produce more power.

- Atkinson Cycle Engines

Regarding the Atkinson cycle engine, it is well known to be an efficient engine, and it is widely used for hybrid vehicles. It is a four-stroke cycle engine (similar to an old engine) but the valve timing is new, the intake valve has a longer open duration than normal. This architecture has to give up some power to achieve higher thermal efficiency and is therefore well suited for the flat-or-always-speed paradigm that is favoured in hybrid vehicles, e.g. Fuel economy/emissions are both maximized when the engine is running in a wide dynamic speed range.

- Two-Stroke Engines

Two-stroke engines are simpler to design than four-stroke engines, but less fuel-efficient and have an environmental penalty in the form of the exhaust. These engines perform a power cycle in a mere two strokes intake and compression in one stroke and power and exhaust in the other (maximum power). Because of their small size and ease of power, they are yet employed in light vehicular applications such as motorcycles, mopeds, and outboard motorboats.

- Variable Compression Ratio Engines

Variable compression ratio engines are a new type of design with both high performance and fuel economy. These engines can be easily customized to alter the compression ratio by manipulating the piston geometry or engine morphology. Due to the possibility of dynamic tailoring of the compression ratio, they can be used in any driving situation on the fly, yielding maximum efficiency in the part of the driving cycle where it is most beneficial, and achieving maximum efficiency during cruising.

- Opposed-Piston Engines

In opposed piston engines, two opposed pistons in each cylinder slide in sequence past each other. One effect of this design is the omission of the cylinder head, which would decrease heat, and would also increase efficiency. Opposed-piston engines have a large variety of industrial applications aimed at providing the best-in-class compactness and efficiency, e.g., military and power generation.

- Free-Piston Engines

Free-piston engines are an evolution of opposed-piston engines by removing the crankshaft. They are driven by linear generators to map the piston motion in terms of power. As a consequence of their natural efficiency, these engines should be used as range extenders for hybrid vehicles and/or power generators.

- Stirling Engines

Stirling engines have a special applicability in closed-cycle thermodynamic cycles. They work a piston by gas expansion and contraction under the action of external heat sources, i.e., solar or combustion energy. Stirling engines are targets of high efficiency and low emission engines, thus useful for applications where relatively constant low-speed power is needed (e.g., some eco-friendly cars and stationary electricity generators).

- Compressed Natural Gas (CNG) Engines

Engines that use compressed natural gas (CNG) fuels instead of gasoline or diesel are employed. CNG is a more environmentally friendly variant that offers emission reduction and cost reduction options. One example for these engines is applications in fleet cars, public transport and private cars converted to CNG.

- W engine

The W engine is a special type of common internal combustion (CI) engine, called “W” due to its unusual cylinder arrangements which can be compared with the letter “W. “For this particular arrangement, it is usually fitted in high-performance cars, but together with the small in-space that it has, it has many cylinders.

Types of Car Engines Based on Configuration

In the design of car engines, the number of cylinders can be used as a measure to classify them. Cars today differ in their appearance and equip them with features and functions. Let’s explore these engine configurations in detail:

Twin-Cylinder Engine

Specifically, the twin-cylinder engine is used in motorcycles and scooters. These engines are also typical in their compactness and ease of manufacture. Nevertheless, since they have low power output they are no longer the daily instrument of use for cars.

Three-Cylinder Engine

Three-cylinder powerplants have been the most promising powertrain type for small cars and hatchbacks. Although the number of cylinders in odd numbers can result in some vibration and coarser resolution, recent developments (turbochargers, etc. These have turned them at least into potential engine drives for passenger cars. They offer a balance between fuel efficiency and performance.

Four-Cylinder Engine

The four-cylinder engine represents the most common engine type sold in the passenger and (almost) utility car segments. Enclosed engines are known to be very compact and exhibit a greater power output than three-wheeled ones. They strike a balance between performance and fuel efficiency.

Five-Cylinder Engine

Rare as it may be, unit the 5-cylinder engine has also been fitted to these cars by car companies, such as Volvo and Audi. With this configuration, it is possible to achieve a good performance/efficiency trade off at the service of people looking to stand out from the crowd of four-cylinder, six-cylinder, etc.

Six-Cylinder Engine

Engines with 6 cycles are mainly employed for high-performance and sports cars, etc. They deliver a good power boost and are typically fitted with turbochargers. The pattern of these motors, which is determined by the designer philosophy of the company, can be a row-in-a-line or V-style configuration.

Eight/Ten/Twelve Cylinder Engine

Nevertheless, an engine cubic capacity with as many as 8 cylinders is commonly found in supercars and high-performance luxury vehicles, and V-configuration is a design option implemented when such engine power is needed for maximum power and performance. Maximum power and torque are reached for V8, V10, and V12 engine engines. They are tuned to the absolute performance ceiling and carry the names Ferrari, Lamborghini, and Bentley.

Why is it Worth learning about a car engine?

Visualizing what happens inside the box is of paramount importance, as there are several reasons for this. Knowing how does a car engine work can help car owners avoid improper decisions in terms of maintenance and can help car owners insight into possible problems in the engine when they are actually running. Furthermore, when you are considering purchasing a new car, you want to understand technical terms in the specs document, such as cube capacity, in-line engine, liquid-cooled and so forth. And it will be more useful to you, for the purpose of understanding the inner workings of an engine.

Common Engine Problems And Solutions

| Engine Problem | Possible Causes | Solutions |

| Engine Misfire | – Faulty spark plugs

– Ignition system issues – Fuel injector problems – Clogged air filters – Vacuum leaks |

– Replace faulty spark plugs

– Repair or replace ignition components – Clean or replace fuel injectors – Replace air filter – Fix vacuum leaks |

| Engine Overheating | – Low coolant levels

– Broken radiator or hoses – Faulty thermostat – Broken water pump – Blocked cooling system |

– Refill coolant and check for leaks

– Replace radiator or hoses – Replace thermostat – Replace water pump – Flush and clean the cooling system |

| Oil Leaks | – Worn out gaskets

– Loose oil pan bolts – Cracked engine block – Oil filter issues |

– Replace gaskets

– Tighten oil pan bolts – Inspect and repair cracks in the engine block – Replace oil filter |

| Poor Acceleration | – Clogged fuel filter

– Fuel pump malfunction – Faulty spark plugs – Air filter issues – Throttle body problems |

– Replace fuel filter

– Replace fuel pump – Replace spark plugs – Replace air filter – Clean or replace throttle body |

| Engine Knock (Ping) | – Low-octane fuel

– Incorrect ignition timing – Carbon buildup in the engine – Faulty knock sensor |

– Use higher-octane fuel

– Adjust ignition timing – Perform decarbonization or use a fuel system cleaner – Replace faulty knock sensor |

| White Smoke from Exhaust | – Coolant leaking into the combustion chamber (blown head gasket)

– Cracked engine block or cylinder head |

– Replace head gasket

– Repair or replace cracked engine block or cylinder head |

| Black Smoke from Exhaust | – Over-fueling (too much fuel entering the engine)

– Faulty fuel injectors – Air filter blockage – Bad mass airflow sensor |

– Replace fuel injectors

– Replace air filter – Clean or replace the mass airflow sensor – Repair fuel system for proper fuel mixture |

| Check Engine Light On | – Faulty oxygen sensors

– Malfunctioning catalytic converter – EVAP system leak – Loose gas cap |

– Replace oxygen sensors

– Repair or replace catalytic converter – Fix EVAP system leak – Tighten or replace the gas cap |

| Hard Starting or No Start | – Dead battery

– Faulty starter motor – Fuel system failure – Bad ignition system components |

– Replace or charge the battery

– Replace the starter motor – Repair fuel system components – Replace faulty ignition components |

| Engine Stalling | – Faulty idle air control valve

– Fuel pump issues – Dirty or faulty mass airflow sensor – Bad crankshaft position sensor |

– Replace the idle air control valve

– Replace fuel pump – Clean or replace the mass airflow sensor – Replace the crankshaft position sensor |

Also read- The Science and Engineering of V6, V8, and V12!

Which is the Best Car Engine?

No matter how large the car – a three-cylinder hatchback or a turbocharged V8 – the basic principles behind an engine’s operation remain the same. Knowing, what is and how the components of your engine operate is not only enjoyable but also useful. It guarantees preparations to deal with routine problems, and what your vehicle is capable of. Just look after your engine and it will look after you on the road.

Check this out– Why is It Important To Change Your Engine Oil Regularly?

FAQ’s

Q1 – What type of engine is used in cars?

A car engine is an internal combustion engine. There are different kinds of internal combustion engines. Diesel engines are one type and gas turbine engines are another.

Q2- What is the function of a car engine?

The purpose of a gasoline car engine is to convert gasoline into motion so that your car can move.

Q3- What are the parts of a car engine?

The core of the engine is the cylinder, with the piston moving up and down inside the cylinder. Other key parts include the spark plug, valves, piston, piston rings, connecting rod, crankshaft and sump.

Q4- How does a car engine work, step by step?

Almost every car with a gasoline engine uses a four-stroke combustion cycle to convert gasoline into motion. They are intake stroke, compression stroke, combustion stroke and exhaust stroke.

Q5- Why won’t my engine start?

Three fundamental things can happen a bad fuel mix, lack of compression or lack of spark. Beyond that, thousands of minor things can create problems, but these are the “big three.”

Q6- How long does a petrol/diesel engine last?

The lifespan of a petrol or diesel engine can vary widely based on several factors, including maintenance, driving habits, engine design, build quality and conditions of operation. Typically, petrol engines can last up to 5,00,000km with proper care and regular maintenance while diesel engines can last longer, up to 8,00,000km due to their comparatively robust construction.

Q7- Why are turbo/superchargers used in already powerful car engines?

Turbo/superchargers are used in car engines to provide drivers with power on demand. Drivers seeking power and performance from their drives generally purchase cars with these types of engines.